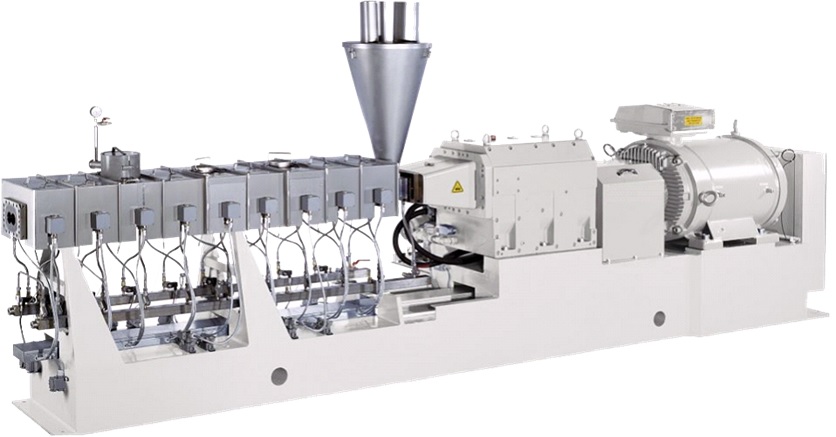

It is the only company in the world which supplies process optimized extrusion lines (PVC extrusion and Compounding) developed and manufactured on its own.

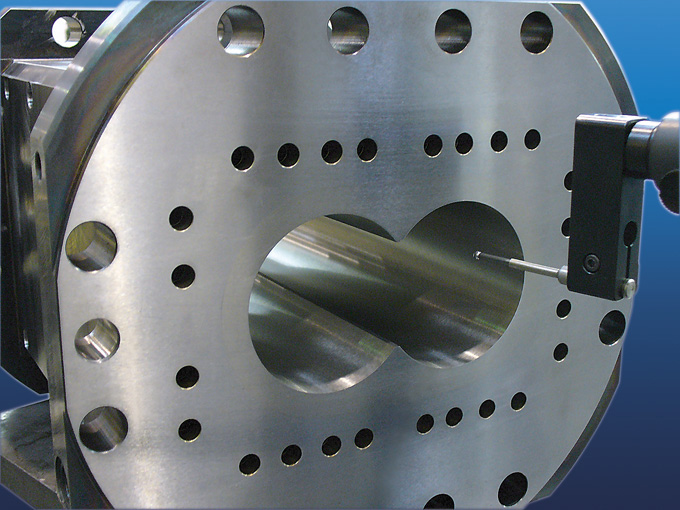

Many companies claim they can build perfect components for extrusion lines, but what about the perfect interaction of these components operating as a whole? Theysohn understands the entire extrusion process and technology, and aligns the individual components to precisely harmonize with each other.

An entire team of specialized companies is operating at two different locations in Austria and Germany to manufacture top-notch machinery and components. Theysohn counts as the world’s most important profile and pipe producers and also has leading compounding companies among its customers.