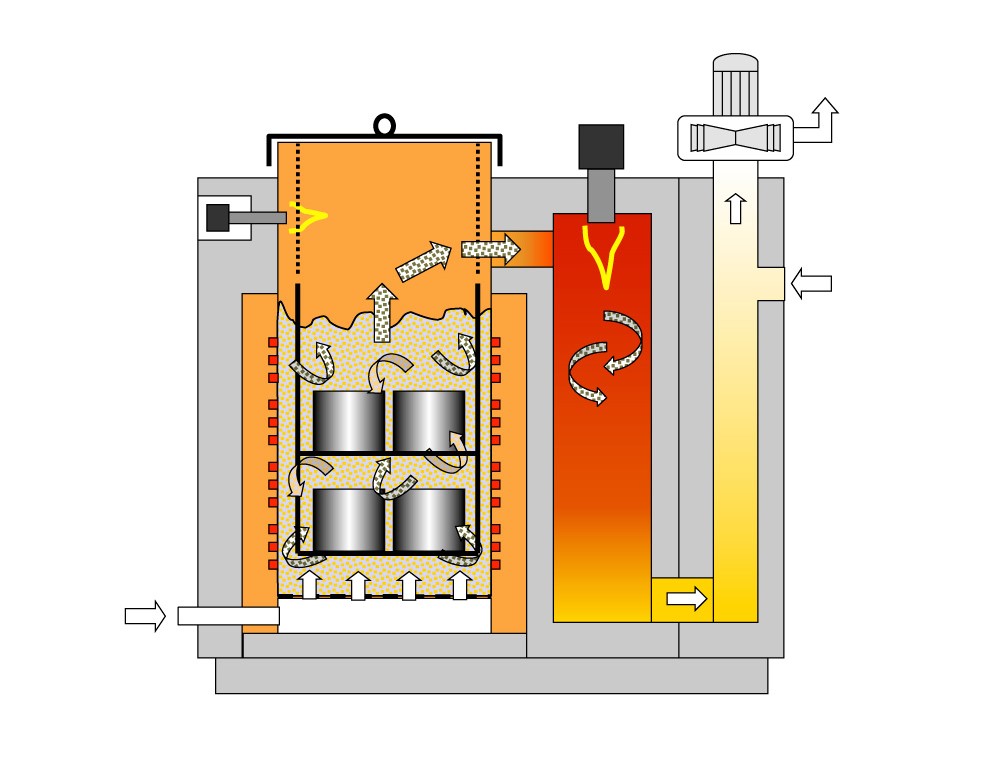

SCHWING is the only manufacturer worldwide who offers all advanced thermal cleaning technologies for the removal of polymers and organic contaminations from metal tools and machine parts of any type and size. Whether using pyrolysis, thermal decomposition under vacuum conditions or a thermal conversion process in a fluidized bed, SCHWING masters all methods to clean components without any residues:

- CLEAN: cleaned perfectly without carbon residues

- QUICKLY cleaned and immediately returned to production

- GENTLE on the part, tool and the environment

- ECONOMICAL in terms of energy consumption and operation

- SAFE through operation with intelligent controls