Reduction Engineering was founded in 1992 preceded by Accu-Grind Inc. which was a service center for industrial knives, such as pelletizer rotors, granulators, and pulverizer discs.

In 1993 Reduction Engineering was started by virtue of a client needing to purchase a better pulverizing system. Word of mouth of a new system for pulverizing roto grade material pushes Reduction Engineering to the forefront and merges with Accu-Grind in 1994.

With the acquisition of the American company Reduction Engineering Scheer Inc. in Kent, Ohio in October 2015 by Maag Pump Systems AG, the Swiss company has added pulverizers to the product portfolio of the Maag group of companies.

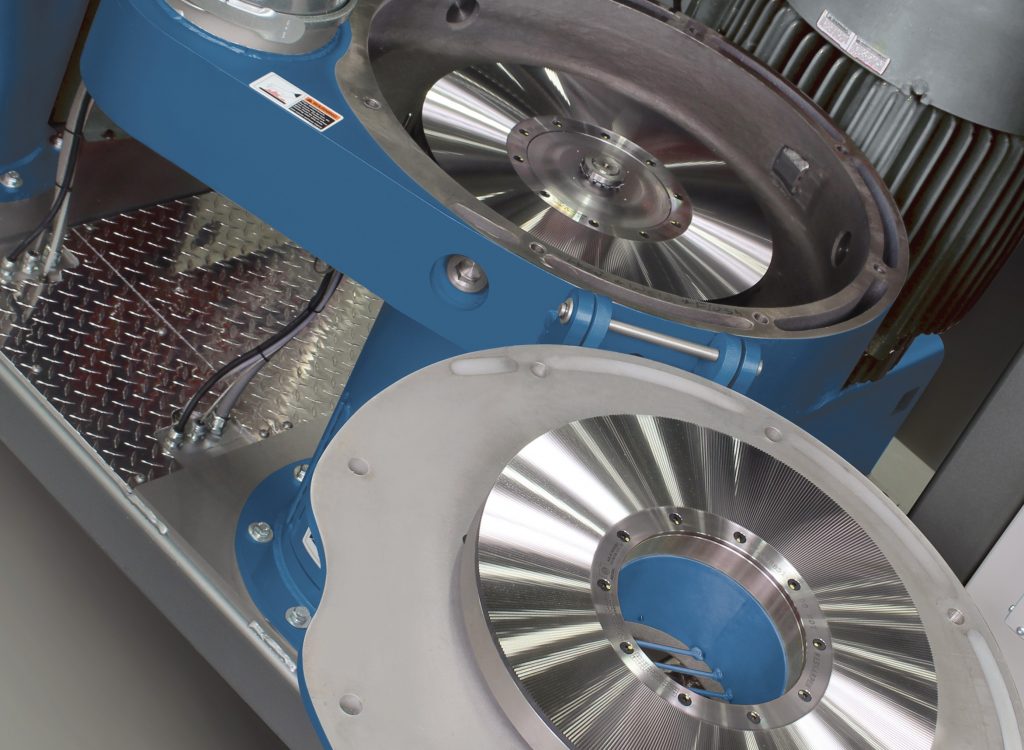

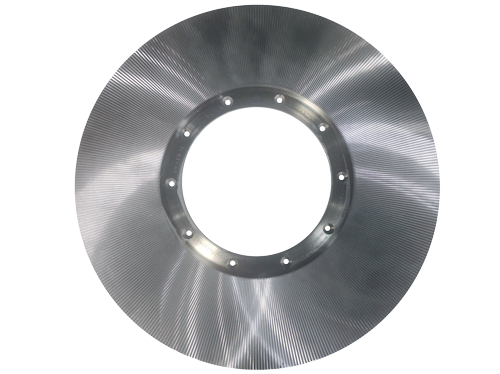

Pulverizers are used to produce powder from plastic pellets or regrind material, usually polyethylene (LLDPE or LDPE), also PP, PVC or ABS.

At the same time a special testing room for pulverizers is set up in the Technical Center in Grossostheim, fitted with two machines of different sizes. A lab pulverizer type RE 25 AC can be used for basic tests or to produce small sample quantities with little effort.