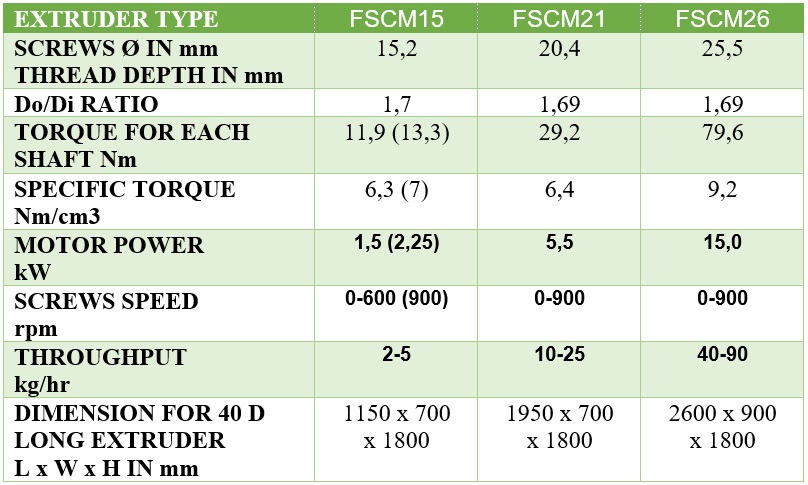

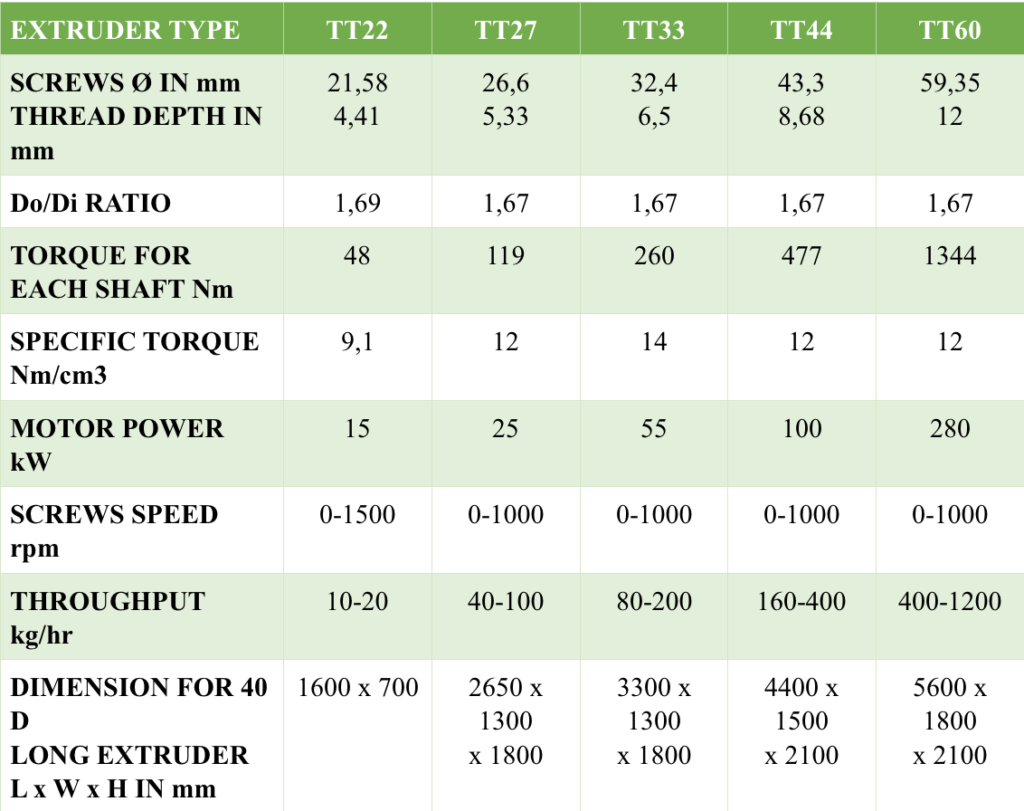

In the spring of 1996, TSA born . Terenghi, Secchi and Aurisano. The union of three experiences, matured in the use, the sale and the mechanical construction of corotating twin screw extruders leads to the realization of a prototype 21 mm in diameter. Five extruders for customers are realized and put into operation. Today, these five machines are still doing their job very well. It’s been nearly 20 years since that day. The extruders products are more than 300. The range has expanded both towards lower and upper diameter machines.

TSA has been in the past twenty years faithful to its mission. Realize simple and high performance machines , maintain a direct relationship with its customers and especially taking pleasure in what he does.